Introducing the Prairie Dog Boring Equipment

Boring with Prairie Dog Underground Boring Equipment is incredibly straightforward. The key to success lies in proper setup. By watching our instructional video, thoroughly reading the provided instructions, and understanding the equipment’s purpose, you can effortlessly and effectively bore a hole.

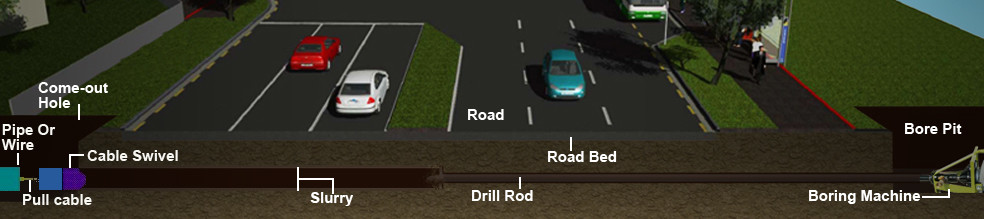

To begin, dig a small trench and align the drill stem within it. Connect your fluid source to the machine and install the drill stem along with the pilot bit. Turn on the water supply to initiate the process.

As the bit rotates, gently move the machine forward. Gradually add more drill stem until you reach your desired target point. Remove the pilot bit and replace it with your preferred size of backreamer. Reverse the machine through the pilot hole using the backreamer.

By following these simple steps, you can efficiently accomplish your boring task with Prairie Dog Underground Boring Equipment.

Ditch the Missiles

Prairie Dog Underground Boring Equipment revolutionizes boring with its precise and reliable capabilities in various soil conditions. Unlike traditional missiles that pose risks and often deviate from targets, our cutting-edge machines offer unparalleled precision and dependability.

Specific soil conditions limit the feasibility of traditional missiles due to their unpredictable trajectory and impact zone. However, Prairie Dog Machines eliminate these limitations. Our advanced technology enables seamless operation in a wide range of soil conditions, ensuring optimal performance on any terrain.

Furthermore, our state-of-the-art machinery eliminates the risk of missiles getting stuck or lost, which can cause significant financial losses and impact critical decision-making. With the Prairie Dog Machine, you can expect exceptional accuracy in boring, avoiding the need for disruptive actions like excavation that could potentially damage surrounding infrastructure.

Investing in Prairie Dog Underground Boring Equipment gives you a competitive advantage in your boring projects. Our meticulously designed equipment surpasses the limitations of traditional missile systems, consistently delivering precise and reliable results that provide peace of mind.

How It Works

Watch the instructional video and refer to the manual for detailed instructions.

Frequently Asked Questions

- How does the Prairie Dog Boring Machine work? The Prairie Dog Boring Machines operate by rotating a carbide-tipped pilot bit to create the initial “pilot” hole. Depending on the machine model, setup may vary, but the goal is to drill a straight-line hole. Water is used to flush the hole as the bit cuts through.

- How much water is required for the process? Under optimal conditions, a 40-foot long, 2-inch pilot hole typically requires between 30 and 50 gallons of water. The water should be supplied at a pressure of around 50-70 psi or standard municipal water pressure and flow. While the machines come with a standard garden hose connection, other connections can be accommodated if necessary.

- How long does it take to complete a bore? The duration of a bore largely depends on the soil conditions. In favorable conditions, a 2-inch by 40-foot bore would usually take approximately 20-30 minutes to complete, depending on the machine model. Back reaming with a 4-inch to 6-inch reamer would take a similar amount of time. As a rule of thumb, adding 20% to the back reaming time is estimated for each 2-inch increment in the finished hole size.

- Does the process create a mess? The amount of mess created is usually less than anticipated. The water combines with the soil to form a slurry, which typically remains near the entrance of the hole. Any additional water runoff can be controlled by excavating a small sump and either allowing it to soak into the ground or pumping it off. The slurry left in the hole acts as a lubricant when inserting casing, cable, pipe, or conduit.

- Can the machine bore through rock? Yes, the machine is equipped with carbide-tipped bits and back reamers that enable it to handle challenging conditions, including boring through rock. The time required to bore through rock depends on its hardness.

- Can the machine be used in sandy areas without cave-ins? Yes, in sandy areas, a mixture of bentonite clay (drilling mud) can be used instead of plain water. This drilling mud helps stabilize the hole in granular soils by preventing water absorption and subsequent weighing down of the sand. Bentonite clay, a naturally occurring soil, needs to be thoroughly mixed with water in a tank but does not need to be overly heavy for boring purposes.

- How does the machine handle sticky clay? Clay can pose challenges for any boring machine. The soil may not mix well in water, making it difficult to exit the hole, or the clay surrounding the hole may swell and constrict the boring rod. Optimum bit speeds are used to shear the clay and create a well-mixed slurry when possible. In cases where clay resists shearing, inexpensive clay inhibitors can be introduced